Enterprise Name: Zhejiang Rigor Logistics technology Co.,Ltd.

Address: No. 518 Huanzhu Road, South Taihu High-tech Industrial Park, Huzhou,Zhejiang 313000,China

Tel:0086-572-2582556

Fax:0086-572-2582596

Mobile:0086-13819216284

E-mail:lihong@rigor56.com

Website:en.rigorwl.com

Carton continuous elevator:

Continuous elevator is used for transporting goods from horizontal direction to vertical direction. Equipped with conveyor lines at the entrances and exits, it can automatically complete the transportation of goods up and down, and can be used for the transportation of goods upstairs and downstairs in factories and logistics centers.

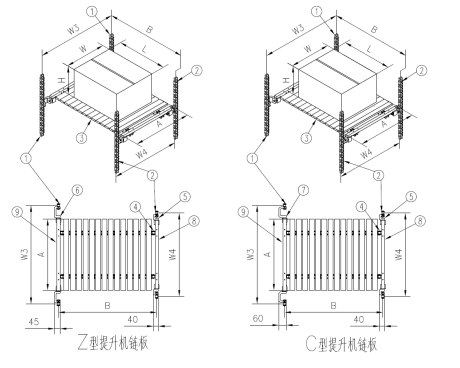

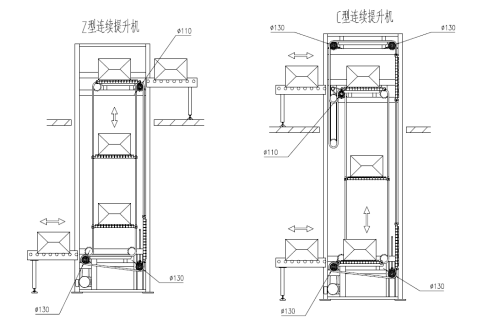

The z-type elevator is the elevator conveying the goods in the "Z" direction, that is, the cargo enters from one side and the output conveying direction from the back side is from bottom to top. Type C elevator is a "C" type elevator, that is, the import and export of cargo transportation are on the same side, and the transportation direction is from top to bottom.

Continuous hoist is a special equipment used for continuous lifting or lowering of unit cargo. Because its chainplate return does not take up the work beat and promotion space, so it has the characteristics of high efficiency, low cost, small occupation space and so on. Compared with the screw chain plate machine, it has a small area, low cost. It is more efficient than a reciprocating elevator.

Applicable conveyors: plastic turnover box, paper packaging, tooling board and hard conveyors with continuous bearing surface on the bottom.

One. main mechanical structure and features:

Body: adopt frame combination structure, mainly composed of upper, middle and lower parts. Adjust the number and length of intermediate frame to meet the needs of different lifting heights. The central column of the frame is made of c-shaped cold-formed sections, which are welded on one side and then bolted to form an independent frame.

Outer sealing frame: wire mesh sealing frame is adopted.

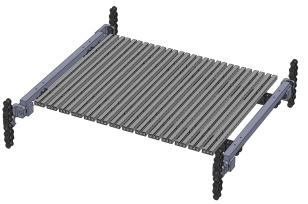

Loading platform: it adopts pallet chain to connect aluminum profiles to form the loading platform. The loading platform is equipped with different u-shaped connectors, which are connected to the lifting chain. As shown in the figure below, the lifting chain runs:

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m. Spraying color shall be specified by party a's color card.

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, plate chain for Oriental special, bearing with seat TR, ha shaft for bearing.

Two. Main performance and parameters:

Z-type continuous hoist (cvc-z)

| 形式描述:Description u 四立柱框架式,标准开模立柱,标准L=2.5m,L<2.5m; Four column frame, standard mold column, standard L=2.5m, L < 2.5m; u 各框架标准模块化; Standard modularization of each frame; u 四链条提升,链条规格16A-1; Four chain lifting, chain specification 16a-1; u 托板链规格16A-TB32; Supporting plate chain specification: 16a-tb32; u 驱动置于提升机底部框架; The drive is placed on the bottom frame of the hoist; u 封框:网片形式,用夹片螺母配合连接; Sealing box, the form of mesh, cooperate to connect with clip nut; u 配合辊道机使用; Cooperate with roller table machine;

|

标准样式Type

| |

名 称 Name | 描 述 Description |

输送物长度L (mm) Delivery length | L=300~1000(若600<L≤1000,框架需非标) L=300~1000(If 600 < L 1000, the frame shall be non-standard) |

输送物宽度 W (mm) Carrier width | W=200~1000(若500<W≤1000,框架需非标) W=200~1000(If 500 < W 1000, the frame shall be non-standard) |

输送物高度H (mm) Delivery height | H≤800 |

下口高度D(mm) Lower jaw height | D≥700(否则挖地坑) D≥700(Or dig a hole) |

上口与机顶高J(mm) Top and top height | J≥H+150+122 |

升降行程E(m) Movements itinerary | E≤20(E=50*n≥C,n为正整数) E≤20(E=50*n≥C,N is a positive integer) |

入口输送机长度F(mm) Length of inlet conveyor | F≥L+250(入口输送机带刹车或阻挡) F≥L+250(brake or block of inlet conveyor belt) |

设备长度L1 (mm) Length of equipment | L1=1510(标准通用) L1=1510(Standard generalized) |

设备宽度 W1 (mm) The device width | W1=1075(标准通用) W1=1075(Standard generalized) |

设备高度H 0 (mm) Equipment height H zero | H0=D+E+J |

楼层开孔尺寸(mm) Floor opening size | (L1+200)*(W1+200) |

地坑尺寸(mm) The pit size | (L1+450)*(W1+350) |

预埋铁尺寸(mm) Embedded iron dimension | (L1+380)* 600 |

电机功率P (kw) Motor power | E≤8m,P=1.5B; 8m<E≤12m,P=2.2B; |

输送速度V(m/min) Delivery speed | V≤40 |

每托板链承载M(Kg) Load per plate chain | M≤50 |

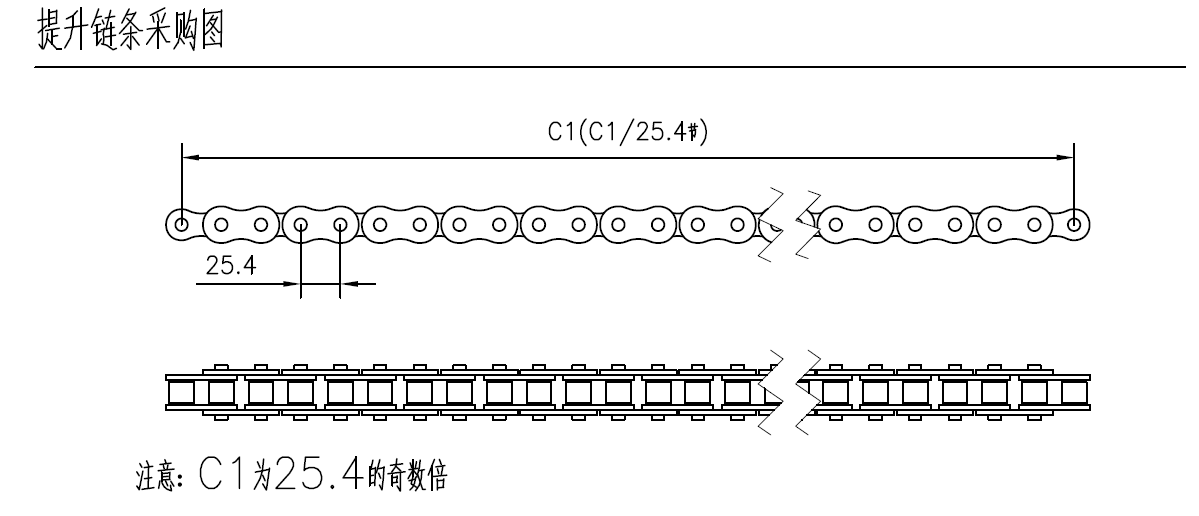

托板链长B(mm) Plate chain length | B=787.4(若非标,则B>L+180且B为25.4的奇数倍) B=787.4(Otherwise, B > L+180 and B is an odd multiple of 25.4) |

托板间距C(mm) Plate spacing | C≥B+H+120且 C为25.4的偶数倍 C≥B+H+120 and C is an even multiple of 25.4 |

托板宽A(mm) Plate A wide | A=570(若非标,则A≥W+100,取整) A=570(If not, then A≥W+100, round) |

提升链环长X(mm) Lift link length | Xmin=2E+2B+900,Xmax= Xmin+300 X为25.4的偶数倍 X is an even multiple of 25.4 |

链板个数Z(个) Number of chain plates Z | Xmin/C<Z<Xmax/C,Z=正整数 Xmin/C<Z<Xmax/C,Z = positive integer (满足效率时,Z取最小值) (when the efficiency is satisfied, Z is the minimum value) |

输送效率η Delivery efficiency vertical | η≤60000*V/C,η<2000件/小时 |

总载荷(Kg) Total load | 310Kg/m+550Kg |

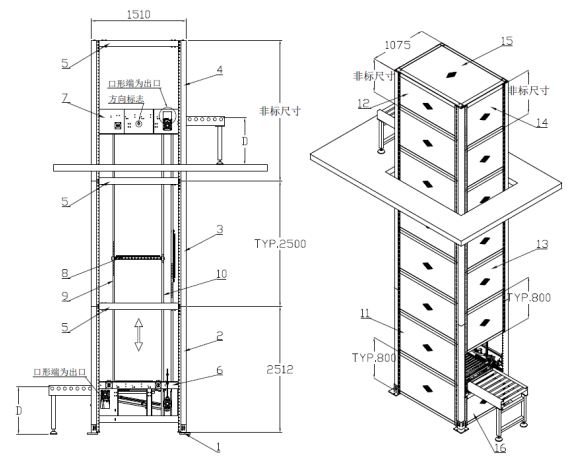

Structure diagram:

序 号 Order number | 名 称 Name | 序 号 Order number | 名 称 Name |

1 | CZVC调节支座 CZVC adjusting support | 11 | CZVC标准侧网片 Standard side mesh of CZVC |

2 | CZVC底部焊接立柱 Weld the CZVC bottom column | 12 | CZVC非标侧网片 CZVC non-standard side mesh |

3 | CZVC标准框架立柱 CZVC standard frame column | 13 | CZVC标准端网片 CZVC standard end mesh |

4 | CZVC非标框架立柱 CZVC non-standard frame columns | 14 | CZVC非标端网片 CZVC non-standard mesh |

5 | CZVC中间圈梁组件 CZVC middle ring beam assembly | 15 | CZVC顶端网片 CZVC top mesh |

6 | CZVC底部框架组件 CZVC bottom frame component | 16 | CZVC入口端网片 CZVC gateway mesh |

7 | CZVC顶部框架组件 CZVC top frame component | 。。。 | 其余网片同样方式设计 The rest of the mesh is designed in the same way |

8 | Z型托板链(见文末详解) Z-plate chain (see details at the end of this article) | ||

9 | 外提升链条 Outside lifting chain | ||

10 | 内提升链条 Inside lifting chain | ||

注:顶部框架有方向标志,安装时注意。 Note: the top frame has direction mark, pay attention when installing. | |||

Type C continuous hoist (cvc-c) :

| 形式描述:Description u 四立柱框架式,标准开模立柱,标准L=2.5m,L<2.5m; Four column frame, standard mold column, standard L=2.5m, L < 2.5m; u 各框架标准模块化; Standard modularization of each frame; u 四链条提升,链条规格16A-1; Four chain lifting, chain specification 16a-1; u 托板链规格16A-TB32; Supporting plate chain specification: 16a-tb32; u 驱动置于提升机底部框架; The drive is placed on the bottom frame of the hoist; u 封框:网片形式,用夹片螺母配合连接; Sealing frame: in the form of mesh, use clip nut to fit and connect; u 配合辊道机使用; Cooperate with roller table machine; |

标准样式Type

| |

标准 Standard | 描述 Standard |

输送物长度L (mm) Delivery length | L=400~1000(若600<L≤1000,框架需非标) L=400~1000(If 600 < L 1000, the frame shall be non-standard) |

输送物宽度 W (mm) Carrier width | W=200~1000(若500<W≤1000,框架需非标) W=200~1000(If 500<W≤1000,the frame shall be non-standard) |

输送物高度H (mm) Delivery height | H=≤500 |

下口高度D(mm) Lower jaw height | D≥700(否则挖地坑) D≥700(Or dig a hole) |

上口与机顶高J(mm) Top and top height | J≥H+150+272 |

升降行程E(m) Movements itinerary | E≤20(E=50*n≥H+B+200,n为正整数) E≤20(E=50*n≥H+B+200,N is a positive integer) |

入口输送机长度F(mm) Length of inlet conveyor | F≥L+250(入口输送机带刹车或阻挡) F≥L+250(Entrance conveyor belt brake or block) |

设备长度L1 (mm) Length of equipment | L1=1660(标准通用) L1=1660(Standard generalized) |

设备宽度 W1 (mm) The device width | W1=1075(标准通用) W1=1075(Standard generalized) |

设备高度H0 (mm) Equipment height H zero | H0=D+E+J |

楼层开孔尺寸(mm) Floor opening size | (L1+200)*(W1+200) |

地坑尺寸(mm) The pit size | (L1+450)*(W1+350) |

预埋铁尺寸(mm) Embedded iron dimension | (L1+380)* 600 |

电机功率P (kw) Motor power | E≤8m,P=1.5B; 8m<E≤12m,P=2.2B; |

输送速度V(m/min) Delivery speed | V≤30 |

每托板链承载M(Kg) Load per plate chain | M≤50 |

托板链长B(mm) Plate chain length | B=787.4(若非标,则B>L+180且B为25.4的奇数倍) B=787.4(Otherwise, B > L+180 and B is an odd multiple of 25.4) |

托板间距C(mm) Plate spacing | C≥2B+H+500且 C为25.4的偶数倍 C≥2B+H+500 and C is an even multiple of 25.4 |

托板宽A(mm) Plate A wide | A=570(若非标,则A≥W+100,取整) A=570(If not, then A≥W+100, round) |

提升链环长X(mm) Lift link length | Xmin=2E+6B+2000,Xmax= Xmin+300 X为25.4的偶数倍 X is an even multiple of 25.4 |

链板个数Z(个) Number of chain plates Z | Xmin/C<Z<Xmax/C,Z=正整数 Xmin/C<Z<Xmax/C,Z = positive integer (满足效率时,Z取最小值) (when the efficiency is satisfied, Z is the minimum value) |

输送效率η Delivery efficiency vertical | η≤60000*V/C,η<2000件/小时 Vertical 60000*V/C, vertical < 2000 PCS/h |

总载荷(Kg) Total load | 310Kg/m+860Kg |

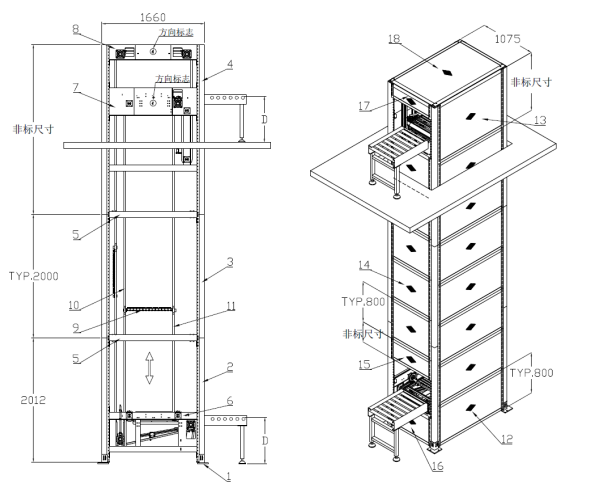

Structure diagram:

序 号 Order number | 名 称 Name | 序 号 Order number | 名 称 Name |

1 | CZVC调节支座 CZVC adjusting support | 11 | 内提升链条 Inside lifting chain |

2 | CZVC底部焊接立柱 Weld the CZVC bottom column | 12 | CCVC标准侧网片 Inside lifting chain |

3 | CZVC标准框架立柱 CZVC standard frame column | 13 | CCVC非标侧网片 Inside lifting chain |

4 | CCVC非标框架立柱 CZVC non-standard frame columns | 14 | CZVC标准端网片 CZVC standard end mesh |

5 | CCVC中间圈梁组件 CZVC middle ring beam assembly | 15 | CCVC非标端网片 CZVC non-standard mesh |

6 | CCVC底部框架组件 CZVC bottom frame component | 16 | CCVC入口端网片 CZVC gateway mesh |

7 | CCVC顶部框架组件 CZVC top frame component | 17 | CCVC出口端网片 CCVC outlet screen |

8 | CCVC顶改向框架组件 CCVC top redirection frame component | 18 | CCVC顶端网片 CCVC top mesh |

9 | C型托板链(见文末详解) Type C carrier chain (see details at the end of this article) | 。。。 | 其余网片同样方式设计 The rest of the mesh design the same way |

10 | 外提升链条 Outside lifting chain | ||

注:各框架组件注意方向标志,同侧同方向安装,详细见文末。 Note: each frame component should pay attention to the direction sign and install in the same direction on the same side. See the end of the article for details. | |||

附:链板详解

Attachment: chain plate, rounding

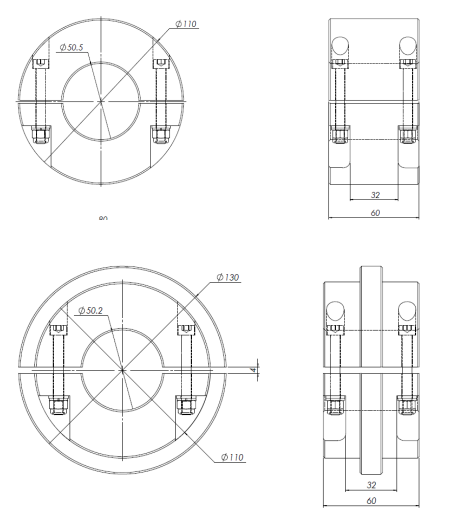

链条托轮详解:

Chain roller details:

Size diagram of roller at each position:

Note: the diameter of the plate chain roller at the top exit position is 110. Please do not use the larger roller, otherwise it will interfere. The rest are using phi 130 large roller. The model is as follows:

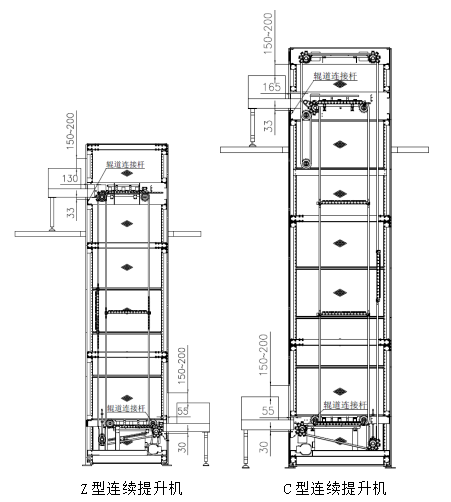

Interface roller table and cover allowance:

序号 The serial number | 尺寸名称(mm) Name of size | Z型连续提升机 Z type continuous hoist | C型连续提升机 Type C continuous hoist |

1 | 下口辊道伸进量 Lower roller table penetration | 85(辊道切斜口110) 85(cutting bevel of roller table 110) | 85(辊道切斜口110) 85(cutting bevel of roller table 110) |

2 | 下口辊道高度余量 Allowance for lower roller table height | 30 | 30 |

3 | 上口辊道伸进量 Upper roller table penetration | 160(辊道切斜口185) 160(cutting bevel of roller table 185) | 145 |

4 | 上口辊道高度余量 Allowance for upper roller table height | 33 | 33 |

5 | 接口处网片高度间隙 Height clearance of the interface mesh | H+150~H+200 | H+150~H+200 |

注:H为货物高度。 Note: H is cargo height. 序号1.3的尺寸对应各立柱的外侧面,2. 4的尺寸对应各框架的辊道连接横档,序号5则对应辊道机辊面的高度。 The dimension of serial number 1.3 corresponds to the outer side of each column, the dimension of 2.4 corresponds to the roller table connecting the transverse file of each frame, and the dimension of 5 corresponds to the height of the roller surface of the roller table machine. | |||

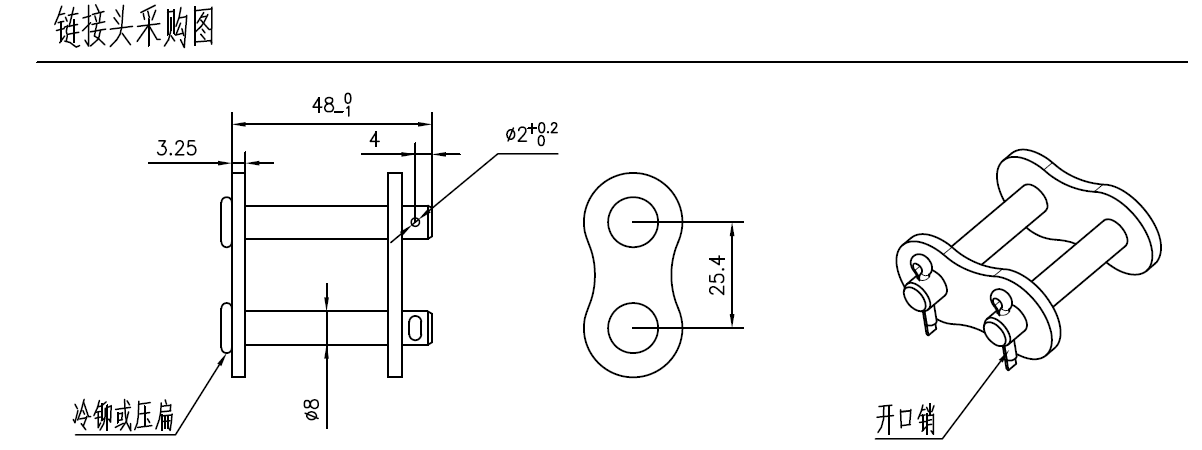

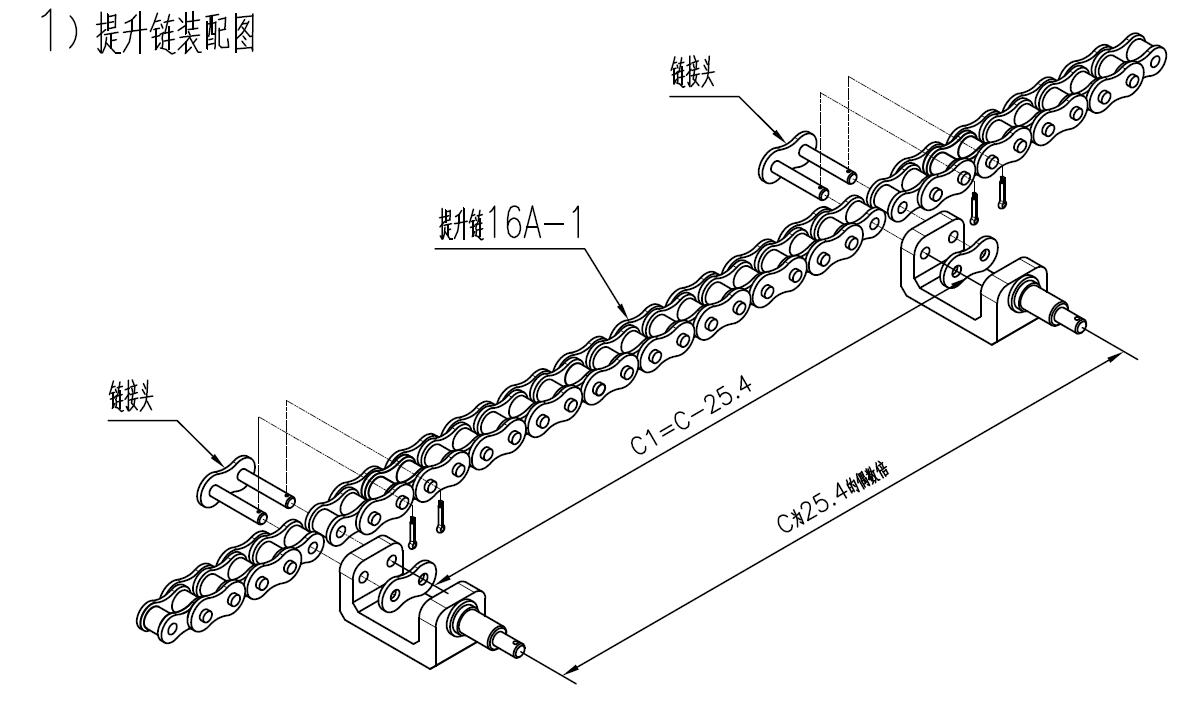

Chain assembly details:

Frame installation direction:

框架名称 Name of the framework | 附图 Attached drawing | 备注 note |

Z型底部框架 Z bottom frame |

| |

Z型顶部框架 Z top frame |

| 按出口及上下方向标志确定安装方向 According to the export and the up and down direction sign installation direction |

C型底部框架 C bottom frame |

| |

C型顶部框架及 顶改向框架 Type C top frame and top redirection frame |

| 按出口及上下方向标志确定安装方向,上下标注为半箭头标志,需同侧同方向安装。 Direction signs in accordance with the export and determine the installation direction, up and down in half an arrow mark, need to be same direction installation on the same side. |