Enterprise Name: Zhejiang Rigor Logistics technology Co.,Ltd.

Address: No. 518 Huanzhu Road, South Taihu High-tech Industrial Park, Huzhou,Zhejiang 313000,China

Tel:0086-572-2582556

Fax:0086-572-2582596

Mobile:0086-13819216284

E-mail:lihong@rigor56.com

Website:en.rigorwl.com

Carton vertical sorting machine:

The main working principle of vertical sorting machine is that the chain consists of two large sprocket wheels rotating through the chain. The fork part on the chain is used to pick up the goods when passing through the roller table machine, and then put it into another roller table line to complete the sorting action of the goods by moving the receiving roller table.

Vertical sorting machine can satisfy the input and output of multiple ports, and also can satisfy the input and output of the same port.

One. main mechanical structure and features:

Body: hot rolled steel Q235/t5 is adopted for the frame, and polymer material is adopted for the chain bar.

Support: folding and welding type support, made of 5mm hot rolled steel plate bending and welding, connected with the frame bolt, and can be connected to the ground by adjusting the foot base, conveying surface height adjustment +25mm.

Drive device: motor drive

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m. Spraying color shall be specified by party a's color card.

Purchased parts configuration: motor adopt SEW, chain adopt donghua, bearing base adopt TR, bearing adopt ha shaft.

Two. Main performance and parameters:

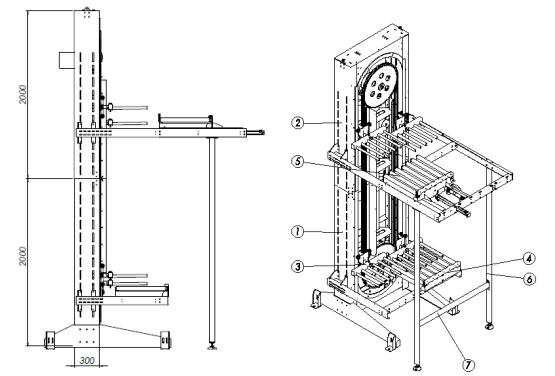

| 形式描述:Description u 整体框架式,标准300mm宽立柱,标准高度L=2m,若L<4m,整体一体机架; Integral frame type, standard 300mm wide column, standard height L=2m, if L < 4m, integral frame; u 各框架标准模块化; Standard modularization of each frame; u 链条规格16A-1; Chain specification 16a-1; u 链轮规格16A-1-76Z; Sprocket wheel specification 16a-1-76z; u 驱动置于提升机顶部框架; The drive is placed on the top frame of the hoist; u 配合辊道机或链条机使用; Use with roller table machine or chain machine; |

标准样式Type

| |

名 称 Name | 描 述 Description |

输送物长度L (mm) Delivery length | L=220~550 |

输送物宽度 W (mm) Conveying width | W≤500 |

输送物高度H (mm) Transport height | H≤L |

下口高度D(mm) The mouth height | D≥750(否则挖地坑) D≥750(Or dig a hole) |

升降行程E(m) Movements itinerary | E≤12 |

出入口输送机长度F(mm) Length of inlet and outlet conveyors | F=640 |

设备宽度 L1 (mm) The device width L1 | W1=1071 |

设备宽度 L2 (mm) The device width L2 | W2=1360 |

设备高度H (mm) Equipment is highly | L=E+1200 |

楼层开孔尺寸(mm) Floor opening size | 1200*1270 |

电机功率P (kw) Motor power | E≤4m,P=0.37B; 4m<E≤6m,P=0.55B; 6m<E≤8m,P=0.75B; 8m<E≤10m,P=1.1B; 10m<E≤12m,P=1.5B; |

输送速度V(m/min) Conveyor speed | V≤30 |

每叉板链承载M(Kg) Load per fork plate chain | M≤50 |

叉板长B(mm) Fork plate length B | B=585 |

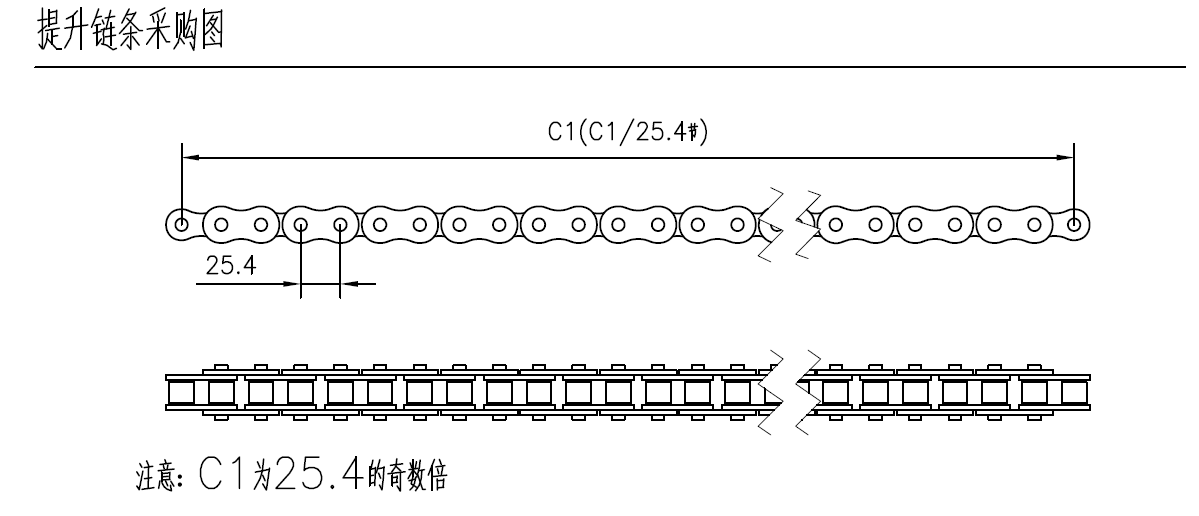

叉板间距C(mm) Fork plate spacing C | C为25.4的奇数倍 C is an odd multiple of 25.4 |

叉板宽A(mm) Fork plate A wide | A=415 |

输送效率η Delivery efficiency vertical | η≤2000件/小时 Vertical 2000 PCS/hour |

总载荷(Kg) The total load | 300Kg/m |

Structure diagram:

序号 Order number | 名 称 Name | 序 号 Order number | 名 称 Name |

1 | VC底部机架组件 VC bottom rack components | 。。。 | 各封板 The seal plate |

2 | VC顶部机架组件 VC top rack components | ||

3 | VC货叉组件 VC fork assembly | ||

4 | VC上货辊道组件 VC roller loading components | ||

5 | VC分拣辊道组件A VC A sorting table component | ||

6 | VC辊道支腿A VC roller support leg A | ||

7 | VC辊道支腿拉杆 VC roller support leg pull rod | ||

8 | 16A-1提升链条 Lift chain 16a-1 | ||

注:标准机架每层高2m。最后一截中间段长度非标 Note: the height of each floor of the standard rack is 2m. The length of the last middle segment is not a standard | |||

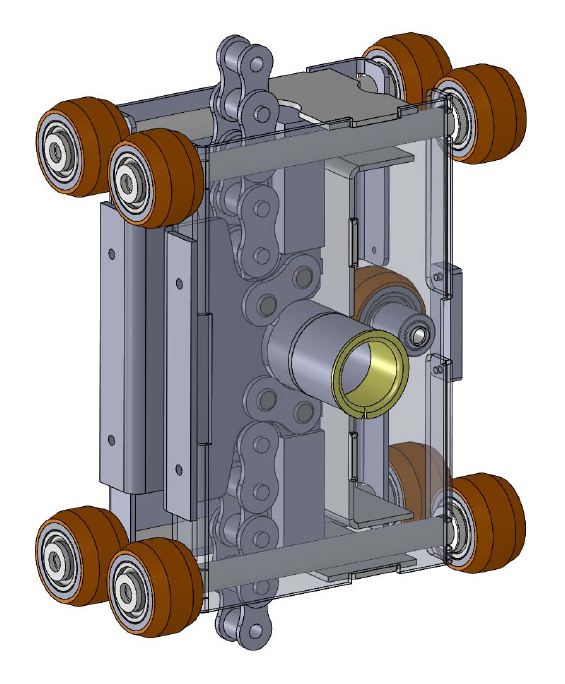

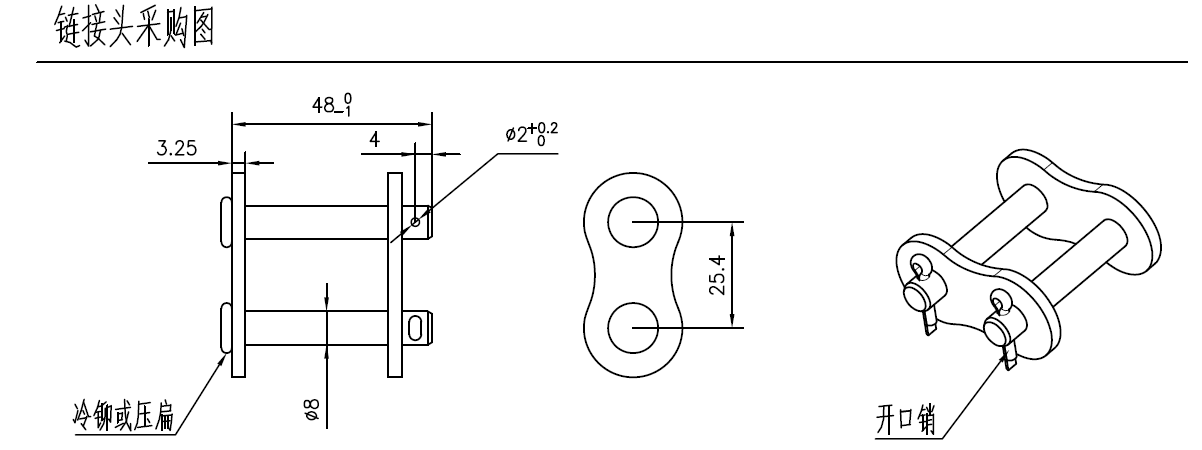

Chain assembly details:

Note: wear two 16a-1-5z chains (including two long link heads) in the body of the car.

Note: with standard link head, 2 for each link.