Enterprise Name: Zhejiang Rigor Logistics technology Co.,Ltd.

Address: No. 518 Huanzhu Road, South Taihu High-tech Industrial Park, Huzhou,Zhejiang 313000,China

Tel:0086-572-2582556

Fax:0086-572-2582596

Mobile:0086-13819216284

E-mail:lihong@rigor56.com

Website:en.rigorwl.com

One. main structure and features:

Guide rail: adopt two aluminum alloy guide rail as the shuttle's walking track, with safety buffer blocking at both ends of the track.

Table carrier: roller table machine/chain machine can be installed and configured according to actual project requirements.

Walking mechanism: high hardness and wear-resisting polyurethane coated walking wheel, driven by motor.

Guide: single side guide wheel guide, reduce the requirement of parallelism of both side guide.

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, bearing with seat TR, ha shaft for bearing.

Surface coating: steel wire brush and sandpaper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 80 m.

Two. Main performance and parameters:

| |

形式描述:Description u 标准铝制轨道h*w=120*90mm,L′≤6m;两铝轨非标长度段每侧一端一根错开布置; Standard aluminum rail h * w = 120 * 90 mm, L '6 m or less; Two non-standard aluminum rail length period of each side with a staggered arrangement; u 标准穿梭小车适用托盘1~1.2m; Standard shuttle car for tray 1 ~ 1.2 m; u 输送高度:542≤H(链式)≤850,535≤H(辊式)≤850; Conveying height: 542 H(chain) 850, 535 H(roller) 850; u 轨道支腿、轨道拉杆等均按标准设计间距设计; Rail leg, rail bar spacing is designed according to the standard design; u 标准采用三相四星柔性一体式滑触线,两端配拉紧器,固定夹板间距F=400mm; Standard three-phase four-star flexible one-piece sliding contact line, the two ends with taut, fixed splint spacing F = 400 mm; u 滑触线运行满一个月后,必须降各紧固件重新拧紧一次; After running for one month, all fasteners must be lowered and re-tightened. u 集电器采用双头集电器; The collector adopts double head collector; u 红外激光测距或条码控制; Infrared laser ranging or bar code control; u 链条机输送面距机架底部默认高度145mm,辊道机为138mm,若非标,使用BOM下图时自行增减至标准高度; Machine chain conveyer surface from the default height 145 mm at the bottom of the rack, roller machine for 138 mm, if not, when using the BOM below to increase or decrease to standard height; u 输送设备需另行下图。 Transportation equipment should be separately below. | |

标准样式Type

| |

名称 Name | 描述 Description |

轨道间距WG(mm) Track spacing WG(mm) | WG=1000(标准间距),非标长度段每侧一端一根 WG = 1000 (standard spacing), non-standard length of a section of each side end |

拉杆间距G(mm) Pull rod spacing G (mm) | 两端部G0=500,G=2000均匀分布,末段不得超过2000 At both ends of G0 = 500, G = 2000 uniform distribution, terminal shall not exceed 2000 |

输送机宽度B或W(mm) Conveyor width B or W (mm) | 850≤B≤1050,1020≤W≤1220 |

支座间距Z(mm) Support spacing Z (mm) | 两端部Z0=300,Z=800均匀分布,末段不得超过800 Z0=300 at both ends, Z=800 evenly distributed, the final section shall not exceed 800 |

托盘长度L0(mm) Pallet length L0(mm) | L0≤1200(若L0>1200,轨道间距需非标) If L0 1200 or less (L0 > 1200, track spacing to non-standard) |

托盘宽度 W0(mm) Tray width W0(mm) | 1000≤W0≤1200(其他值相应修改底部框架和支腿) 1000≤ W0≤1200 or less or less (other values corresponding to modify the bottom frame and leg) |

托盘支脚宽度D(mm) Width of tray foot D(mm) | D≥80(针对链式输送) D≥80 (for chain conveyor) |

输送机长度LS(mm) Conveyor length LS(mm) | LS≥WG+500 |

对接设备安全间距K(mm) Safe distance between docking devices K (mm) | 10≤K≤15 |

输送物高度H0(mm) Conveying height H0(mm) | H0≤800(具体检视货物抗倾倒能力) H0≤800 (inspect the anti-dumping ability of the goods) |

下口高度H(mm) Lower jaw height H (mm) | 542≤H(链式)≤850,535≤H(辊式)≤850; 542≤H(chain)≤850,535≤H(roller)≤850; |

无电箱侧中心到边距离S1(mm) Distance S1 (mm) from center to side of no-power box | S1=810 |

有电箱侧中心到边距离S2(mm) There is electricity box side center to edge distance S2 (mm) | S1=1476 |

设备总长S(mm) Equipment general S (mm) | S=S1+S2=2286 |

极限安全断电距离S0(mm) Limit safe cut-off distance S0 (mm) | S0=500+开关安装位置≈750 S0=500+Switch mounting position≈750 |

行程E(mm) Stroke E (mm) | 按项目要求 As per project requirements |

轨道总长L(mm) Total track length L (mm) | L=E+S+S0*2 |

电机功率P (kw) Motor power | P=2.2B; |

输送速度V(m/min) Conveying speed V (m/min) | V≤160 |

停位精度J(mm) Stop precision J (mm) | ±5 |

整机承载M(Kg) Bearing capacity M(Kg) | M≤1500 |

总载荷(Kg) Total load (Kg) | 40Kg/m+630Kg+M |

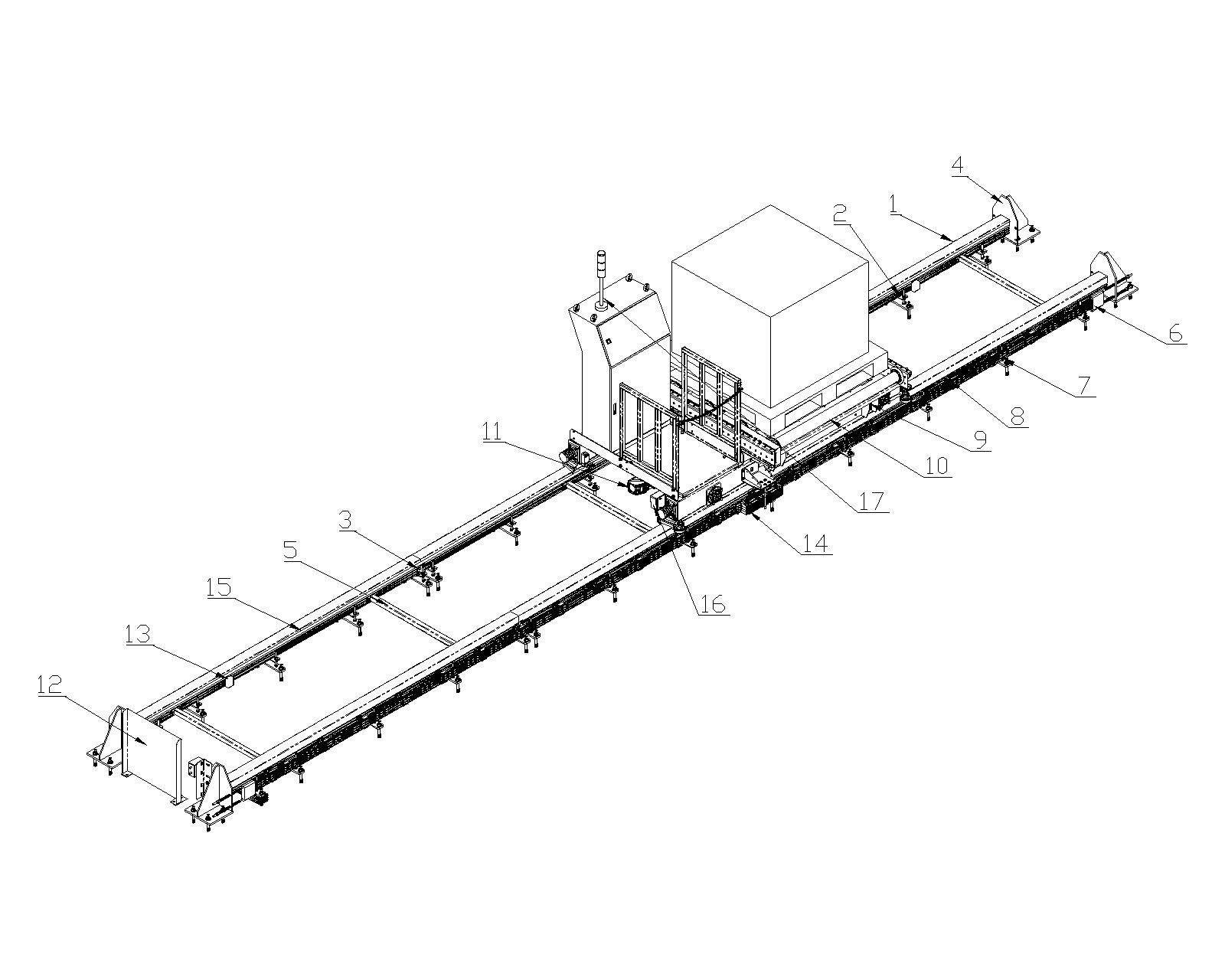

结构简图:

Structural diagram

序 号 Order number | 名 称 Name | 序 号 Order number | 名 称 Name |

1 | 铝型材轨道 Aluminum profile track | 11 | 激光测距仪 Laser rangefinder |

2 | 固定支座 Fixed support | 12 | 测距反光板 Ranging reflector |

3 | 接驳固定座 Connected to a fixed seat | 13 | 断电保护检测板 Power-off protection test plate |

4 | 端部阻挡 End block | 14 | 集电器(双头) Collector (double head) |

5 | 轨道拉杆 Track bar | 15 | 定位条码(可选) Location bar code (optional) |

6 | 滑触线拉紧器 Slide wire tensioner | 16 | 红外通讯器(可选) Infrared com (optional) |

7 | 柔性一体式滑触线 Flexible one-piece sliding contact line | 17 | 三色灯 Three color lamp |

8 | 固定夹板 Fixed splint | ||

9 | 输送机支腿 Conveyor legs | ||

10 | 穿梭车 Shuttle car | ||

注意:Note 1:驱动电机、导向轮及滑触线安装在同一侧; The drive motor, guide wheel and sliding contact wire shall be installed on the same side; 2:货物不得超出托盘; The goods shall not exceed the pallet; 3:激光测距板与阻挡最外侧对齐,防止意外发生时损坏激光测距仪。 laser ranging plate and block the lateral alignment, prevent accident damage to the laser range finder. | |||

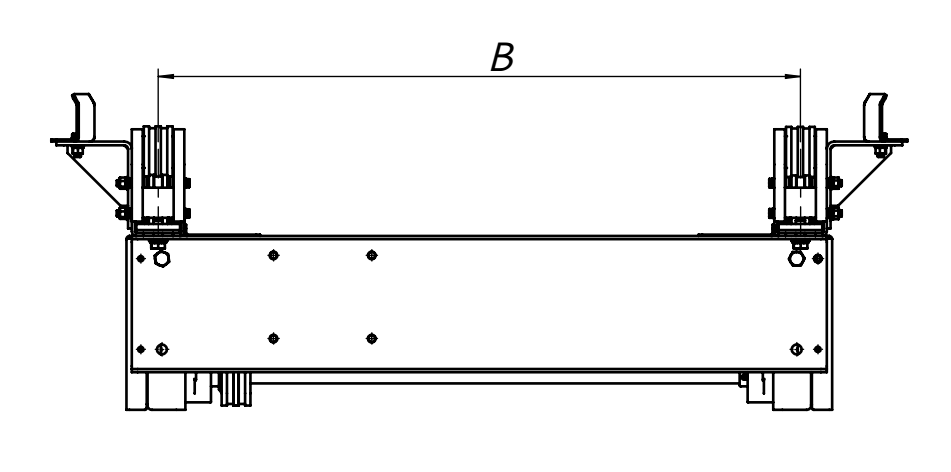

1.1.RGV穿梭小车

1.1.RGV shuttle car

|

形式描述:Description u 标准RGV直线穿梭小车为固定结构;Standard RGV linear shuttle car is fixed structure; u 适用托盘宽度1~1.2m;Suitable for tray width 1 ~ 1.2m u 不含输送设备及支腿。Excluding transportation equipment and leg. |

1.2.RGV地面轨道组件

1.2.RGV ground orbit module

|

形式描述:Description u RGV轨道调整底座,RGV轨道接驳底座,RGV轨道拉杆,RGV滑触线连接组件的数量由轨道总长L决定; The number of rail adjusting base, RGV rail connecting base, RGV rail pull rod and RGV sliding contact wire connecting assembly is determined by rail total length L; u 道总长L=E+S+S0*2;Total length L=E+S+S0*2; u RGV轨道垫板为外购件,数量为RGV轨道调整底座,RGV轨道接驳底座总和的一半。 The number of RGV track spacer is one half of the sum of RGV track adjusting base and RGV track connecting base. |

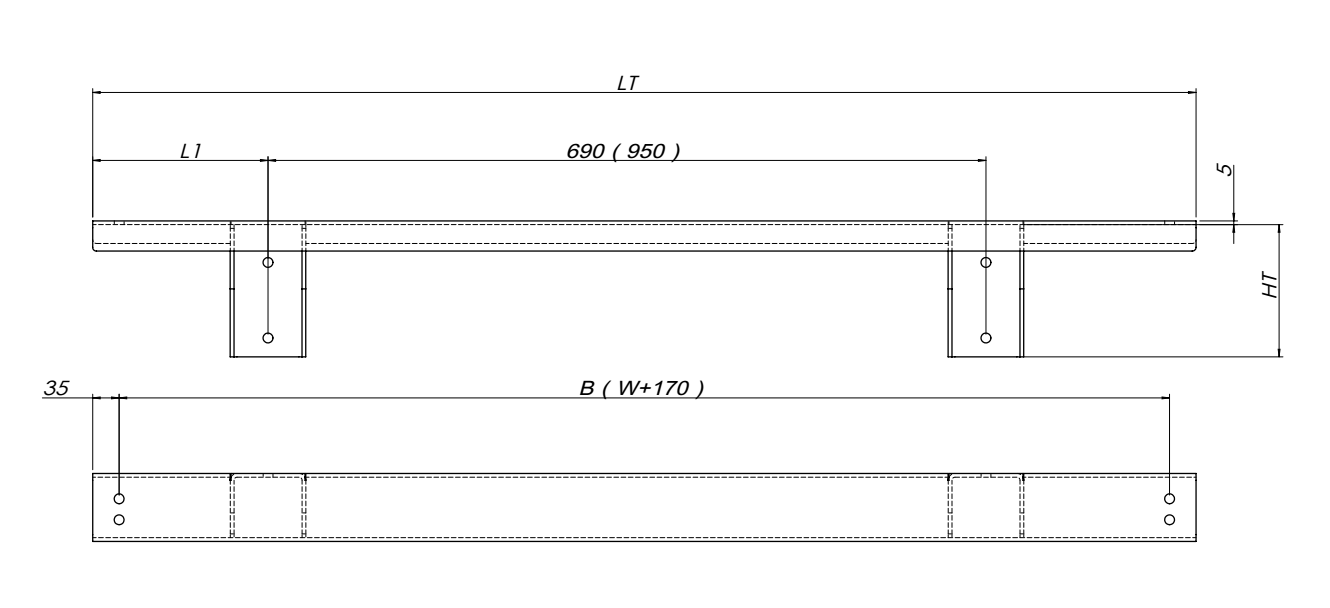

1.3.RGV输送机支腿

1.3. Supporting legs of RGV conveyor

支腿根据输送机的输送形式,宽度和高度的变化均有所不同。具体如下表及示意图:

The supporting leg varies in width and height according to the conveying form of the conveyor. The details are as follows:

序号 Order number | 输送形式 Delivery form | 总长LT(mm) Total length of LT | 安装孔间距JT(mm) Mounting hole spacing JT | 支腿竖档高度HT(mm) Leg vertical height HT | L1 | 备注 note |

1 | 链式 The chain | LT=B+70 | 690 | HT=H-382 | L1=(LT-690)/2 | B为链条机内宽 B is the inner width of the chain |

2 | 辊式 roller | LT=W+240 | 950 | HT=H-375 | L1=(LT-996)/2 | W为辊道机内宽 W is the inner width of roller table |

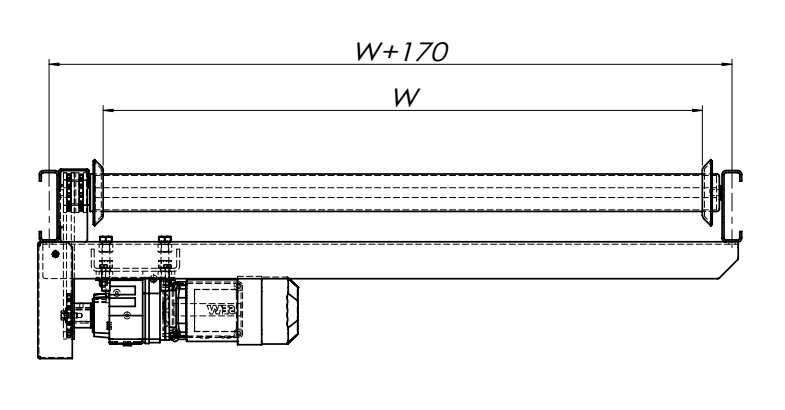

1.4.输送设备

1.4. Conveying equipment

标准的直线穿梭车链式输送设备使用标准链条机(支腿高度为0),辊式输送设备使用标准辊道机。BOM表中不含输送设备,需另外下图。

Standard linear shuttle chain conveyor USES standard chain conveyor (leg height is 0), roller conveyor USES standard roller table. There is no conveying equipment in the table, please refer to the following picture.

1.4.1.链条机

1.4.1. Chain machine

1.4.2.辊道机

1.4.2. Roller machine

1.5.可选附件

1.5. Optional attachments

可选附件中电气元件由电控选择,如型号与标准模型中不一致,需根据实际情况重新设计各安装板或安装架。选择后按照部件清单下图。

Optional accessories of electrical components by electronic control options, such as model and standard model of inconsistencies, should be installed according to the actual situation to redesign the board or frame. Select and follow the parts list below.

1.5.1.可选附件简图

1.5.1. Optional attachment diagram

序号 Order number | 名称 Name | 示图 Shown in figure | 电气元件品牌型号 Electrical components brand model | 备注 note |

1 | RGV激光测距组件 RGV laser ranging module |

| 劳易测激光测距仪 Lloyd's laser range finder AMS 304i 40 | 按项目需要在RGV激光测距组件和RGV读码组件中选择一种 Select one of the RGV laser ranging module and the RGV code reading module as required by the project |

2 | RGV测距反光架 RGV ranging reflector |

| 无 There is no | 对应RGV激光测距组件选择 Corresponding RGV laser ranging module choice |

3 | RGV读码组件 RGV code reading component |

| 倍加福扫码头PCV100-F200-B17-V1D Double blessing sweep dockPCV100-F200-B17-V1D | 按项目需要在RGV激光测距组件和RGV读码组件中选择一种,与RGV条码对应。 According to project requirements, select one of the RGV laser ranging module and the RGV code reading module, corresponding to the RGV bar code. |

4 | RGV红外通讯组件 RGV infrared communication module |

| SICK红外线数据传送器ISD400-6111 SICK infrared data transmitter isd400-6111 | 按需选择,对应RGV地面红外通讯组件 Select as needed, corresponding RGV ground infrared communication module |

5 | RGV地面红外通讯组件 RGV ground infrared communication module |

| SICK红外线数据传送器ISD400-6111 SICK infrared data transmitter isd400-6111 | 按需选择,对应RGV红外通讯组件 Select as needed, corresponding to RGV infrared communication module |

1.5.1.可选附件清单(实际按项目需要选取)

1.5.1. List of optional attachments (actually selected according to project needs)

项目单号:Project number | ||||||||

序号 Order number | 编码 coding | 设备代号 Equipment code | 名称 Name | 图号 Drawing number | 单位 unit | 数量 quantity | 设计员 designer | 备注 note |

1 | 22.1.94.0000.0000 | RGV激光测距组件 RGV laser ranging module | RGV.01.13 | PCS | 1/套 One / set | 若有 If any | ||

2 | 22.2.91.0000.0000 | RGV测距反光架 RGV ranging reflector | RGV.02.09 | PCS | 1/套 One / set | 若有 If any | ||

3 | 22.1.93.0000.0000 | RGV读码组件 RGV code reading component | RGV.01.12 | PCS | 1/套 One / set | 若有 If any | ||

4 | 22.1.95.0000.0000 | RGV红外通讯组件 RGV infrared communication module | RGV.01.14 | PCS | 1/套 One / set | 若有 If any | ||

5 | 22.2.92.0000.0000 | RGV地面红外通讯组件 RGV ground infrared communication module | RGV.02.10 | PCS | 1/套 One / set | 若有 If any | ||