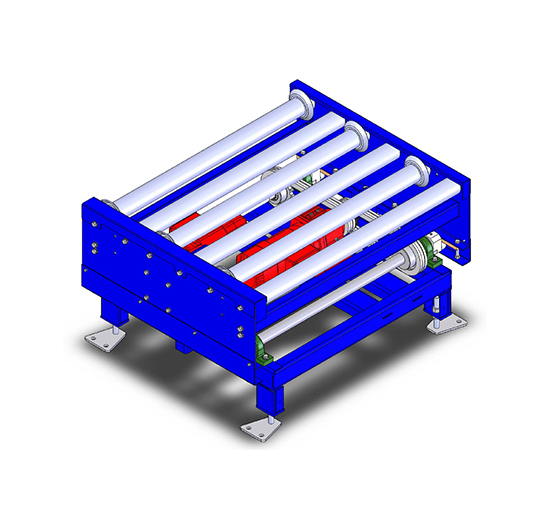

Pallet lift transfer unit:

One. main structure and features:

Jacking mechanism: welding type bottom frame with height adjusting foot, base type deceleration motor is placed in the middle of the bottom frame, two shafts are connected by bearing pedestal and bottom frame on both sides respectively, two shafts are connected with the motor by driving chain respectively. Each shaft and both ends are equipped with needle roller bearing crank arm to form the jacking structure.

Load shifting mechanism: adopt double chain roller table machine, the specific structure is the same as the foregoing.

Accessory device: photoelectric support (lift two positions, in place detection).

Purchased parts configuration: reducer motor SEW, chain for hangzhou donghua, bearing with seat TR, ha shaft for bearing.

Surface coating: steel wire brush, sand paper are used to remove rust, acid wash to remove grease. After phosphating, the surface is sprayed with epoxy powder and baked. The thickness of resin is between 60 m and 90 m.

Two. Main performance and parameters:

| 形式描述:Description u 双链传动滚筒(10A-13Z)Φ76×3mm/Φ89×3mm Double-sprocket roller (10A-13Z) Φ76×3mm/Φ89×3mm u 滚筒挡圈导向 Side guide on roller u 机架型钢 125×70×15×5mm Side profile 125×70×15×5mm u R系列内置电机 R series gear motor u 凸轮升降,行程70mm Lift height 70mm |

标准样式 Type | |

标准 Standard | 描述 Description |

本体长度Length (mm) | L=B(Chain conveyor)-100 |

高度Height (mm) | H(min)≥450 |

挡圈内宽B (mm) Inner width | 770 ≤ B ≤ 1520(SEW motor); 670 ≤ B ≤ 1520(Taiwan motor) |

电机功率P (kw) Motor power | Lift:0.75~1.5 Transfer:0.37~0.75 |

输送速度V (m/min) Line speed | V=12 V=16 V=18 |

升降时间 (S) Lifting time | 2.3 (单行程 Single trip) |

最大承载 Max payload (Kg) | Max ≤1500Kg |